Choose well

Designing Antarès riding helmet

7 November 2022

Choose well

7 November 2022

A riding helmet, or hat, is a vital piece of equipment for your safety when out on your horse. While safety is the hallmark of all Antarès helmets, style and aesthetics are still just as important today. But, what does all that matter if the helmet isn’t comfortable? So, there are a plenty of qualities and criteria to consider when designing a new helmet.

In this article, we’ll give you a sneak peek at the process to make Antarès riding helmets. From research and development to the arena, you’ll get the inside line on what makes our helmets so special.

Each design process for Antarès riding helmets starts with a product manager. After thoroughly reviewing the sector, he/she lists all key rider requirements in a user design brief. These must be factored in to the design process. The brief is then presented at a product launch meeting with the designer, buyer and engineer working on the project. This is when the choice of guideline standards is made. Those applying to each riding hat can be European or American, however, our helmets meet each one of these standards.

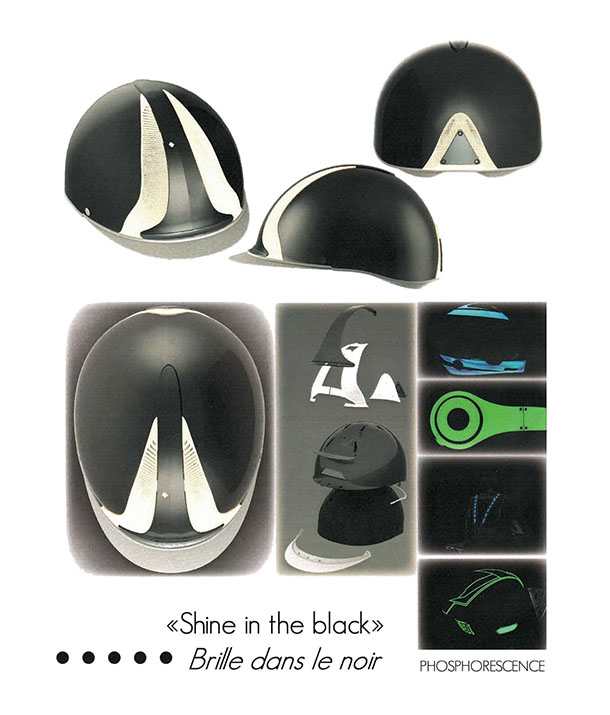

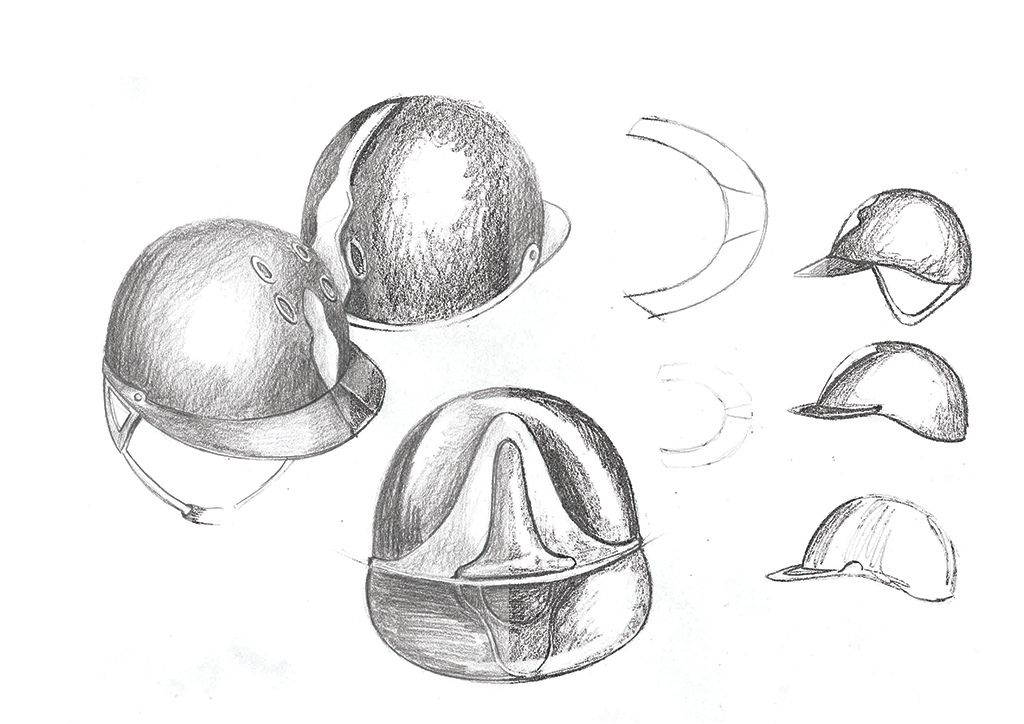

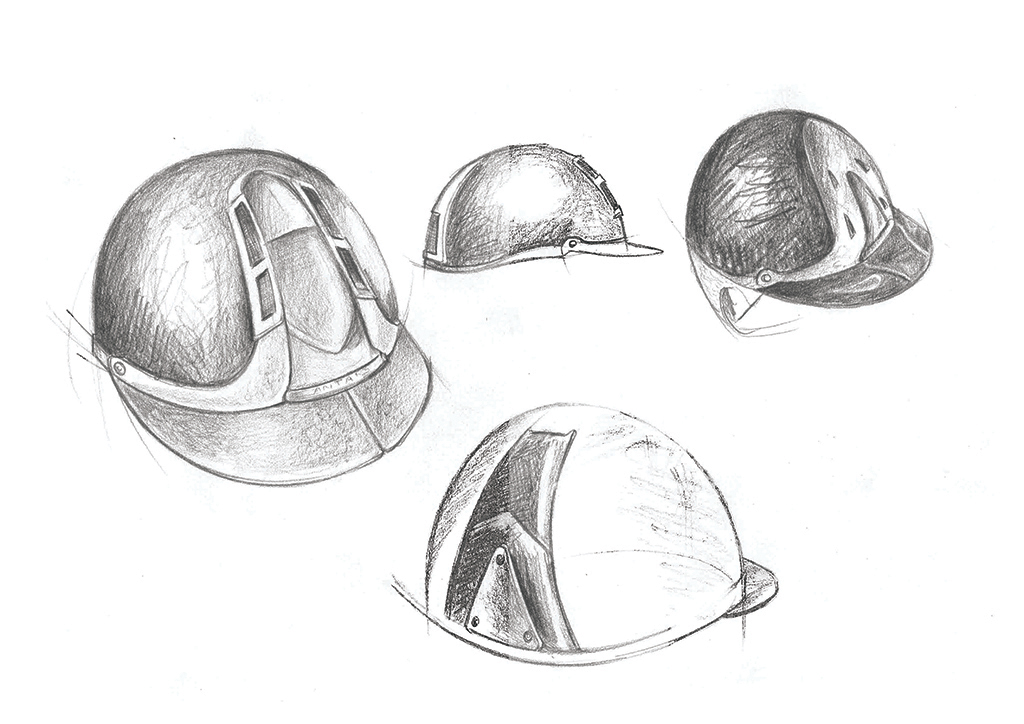

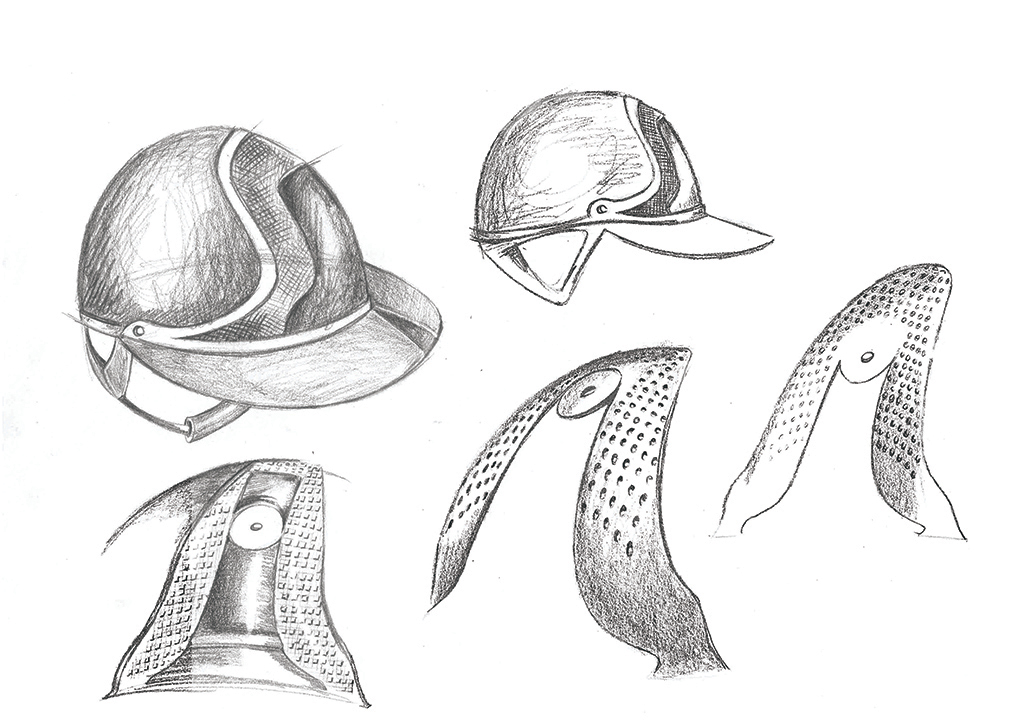

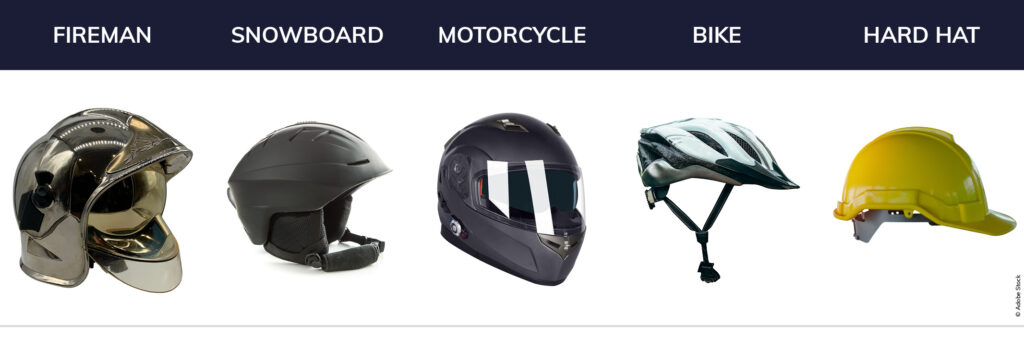

The process starts with initial research to identify the choice of helmet. The sources of inspiration to be ever more innovative can vary widely and are sometimes far removed from horse riding. 2D sketches, called “rushes” are made.

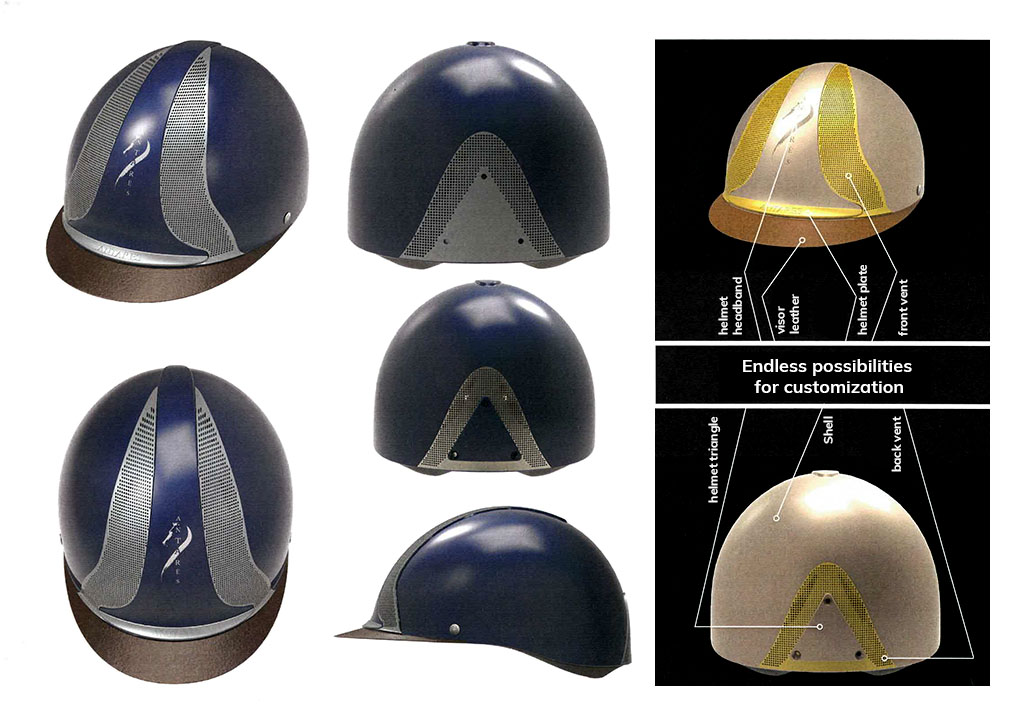

Once the desired trends and touches for the future Antarès riding helmets have been selected, the 3D design process begins. This task is split into two parts:

–3D style : modelling led by the project designer. This stage finalises the shape, size and air vents for the future helmets, tailored to rider requirements stated in the user design brief.

–3D technical modelling: The design engineer takes the 3D style model and builds in the technical features required by applicable standards. The engineer also has to deal with the comfort and fit of the future Antarès riding helmets.

Once these initial 3D models have been produced, the buyer works with the supplier to get product cost estimates. Production tool costs are also assessed. Only when all these aspects are given the green light does the project move to the next step.

Once the product manager has given the green light for the project and signed off the costs, research into toolmaking begins (3D designs for tools used to craft helmet components like the outer shell and helmet liner). When the riding helmet designs have been approved, work switches to producing ‘trial’ models in our Saintes workshops. The first components are made and assembled to produce the future helmet.

Once the ‘trial’ helmets have been assembled, a panel of staff from our Saintes workshops tests them out wearing them stood still. This helps to ‘unofficially’ check one last time for real that,

(i) the helmet sits properly on the head, i.e., that it fits different shapes of head nicely,

(ii) and that there is no discomfort, pressure or pain, particularly to the forehead, temples and back of the head.

Next, the helmets are dispatched to an authorised laboratory to check they meet the standards. The aim is to pass the various test requirements so that they can retailed on the market. See our blog article on “The riding helmet: Central to safety” for a test demonstration on one of our helmets.

Once the laboratory certifies and licences the Antarès riding helmets, production kicks in.

Once the tools, leather and parts of the future helmets have been delivered to our workshops in Saintes, production begins. The future pieces of leather are cut out using digital jigs, before being stitched and dyed, together with the harness and visor. At the same time, any personalised helmet accessories are prepared.

Once that is done, Maëva, Cécile, Lydie, Sandra and Emilie get on with assembling the finished helmet. They each have an assembly trolley which they set out based on the product specifications. While the assembly trolley layouts are changed on a daily basis, production arrangements are made weekly. Each trolley contains enough parts to make 10 Antarès riding helmets.

The shell, the air vent kit, the initial leather parts, the triangle, headband, visor and harness are assembled. Once this key task is done, the finishing touches can be made by riveting (clipping) the harness to the helmet. The rivets correspond to the harness anchor points, and then the liner is fitted.

When the helmet is finished, it goes to quality control. Aesthetic and technical aspects are inspected. Components must be properly glued in place while the helmet must be scratch and blemish-free. The riveting and liner attachments are safety tested, while the regulatory standard labels are checked so that they are properly displayed on the liner.

The pads are then added to the Antarès riding helmet, together with a user manual. Finally, the helmet is bagged, boxed and shipped to your address.

To help you buy the right helmet for you, we’ve written an article entitled, “How to choose your riding helmet“, including a “helmet fitting” video and advice from an Antarès specialist.

350,00€

The Galaxy helmet features unique color combinations, contrasting stitching and chrome detailing on the shell. Its timeless design adds to the comfort of a breathable helmet. A helmet conforming to European standards, it enables riders to ride in complete safety. The Eclipse visor gives the helmet a stylish, elegant finish. Its size, larger than a conventional visor, protects you from the sun during your riding sessions in the arena or outdoors.

400,00€

With its matte black shell and brown or black leather finish, the Référence helmet is sober and classic. Its timeless design combines with the comfort of a breathable helmet. The helmet conforms to European and American standards, enabling riders to ride in complete safety. The Eclipse visor gives the helmet a stylish, elegant finish. Its size, larger than a conventional visor, protects you from the sun during your riding sessions in the arena or outdoors. The rhinestones on the visor add a touch of glitter.

450,00€

The Premium helmet features a glossy shell finish. For an aesthetic design, the leather and shell are color-matched. It is available in 5 shell colors. Its timeless design adds to the comfort of a breathable helmet. A helmet conforming to European and American standards, it enables riders to ride in complete safety.If out of stock, lead time 6 to 8 weeks for size L.

550,00€

The Classic helmet combines Alcantara and leather for the shell. The shine of the headband adds elegance to the sobriety of Alcantara. Its timeless design adds to the comfort of a breathable helmet. A helmet that conforms to European and American standards, it enables the rider to ride in complete safety.If out of stock, lead time 6 to 8 weeks for size L.