R&D

Antarès leather saddle creation

16 June 2023

R&D

16 June 2023

Designed to ensure the well-being and comfort of the horse/rider couple, our custom-made saddles are created, from their origin, in our workshop in Saintes in Charente Maritime. Each riding saddle requires many hours of work from our craftsmen and requires 75 pieces of leather and foam. It is a long and multi-step process.

Our 45 saddlers deploy all their know-how to offer you saddles that meet the values of requirements characterizing Antarès saddles.

The raw leather, of French origin, must be cut and prepared in our workshop in Saintes. In a constant search to improve the working conditions of our saddlers, we have automated certain tasks.

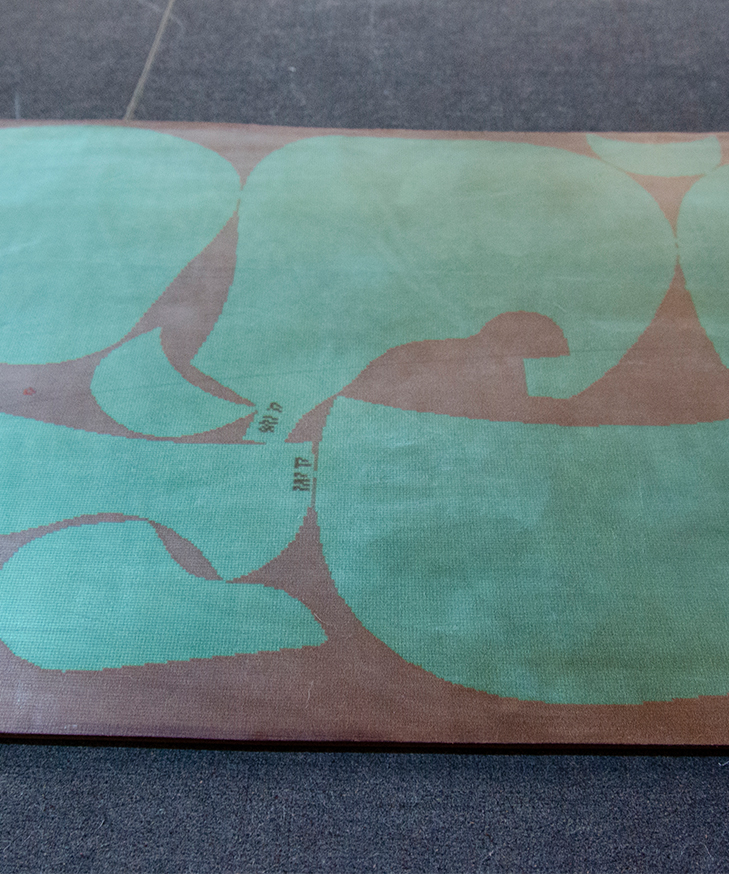

As of July 2020, the Antarès leather workshop boasts digital cutting machines to cut the leather hides.

The leather hide is laid out on a machine that flattens it to eliminate wrinkles and creases. The saddle maker then positions the part templates, one by one, on the hide using a projector.

The quality of the leather can then be customised to each part based on its function and position on the saddle. The smoothest leather comes from the cow’s hindquarters. The saddle maker must be perfectly familiar with the leather and each part of the saddle to find exactly the right place for them on the hide.

Once the templates are in place, the machine cuts the parts, following the outlines of the projected images.

Each part of the saddle is treated differently according to its position and function on the saddle. The parts are :

Each saddle is laser-embossed on the sweat flap. This features the year the saddle was made, its number and specificities

This “ID” certifies the quality and authenticity of each saddle.

If any flaw is detected on a part, it is re-cut using a new hide. The grain of the leather can shrink or expand with moisture and heat. Scars very often appear at different stages of the production process. If this happens, the saddle must be disassembled, the damaged part re-cut and the saddle reassembled.

This process requires many hours of work and numerous saddle makers.

Approximately 75 leather and foam parts of different shape, size and thickness are needed to make a saddle.

Each part must be prepared prior to fitting and final assembly. The number of parts required depends on the saddle type and options.

The assembly process is split into two distinct segments. The parts for mono-flap and double-flap saddles are separated.

The saddle-maker marks the position of the blocks and pads on the sweat flaps by hand. These change depending on the saddle type and the rider size. This information is mentioned by the expert who carried out the fitting. Once in place, the blocks and pads are covered in leather which is stitched, then trimmed.

Memory foam for the knee-rolls is covered in soft leather. The Antarès logos are matched to the customer’s choice of saddle colour and top-stiched in.

Grained reinforcements to protect the lower flap stitching, gullet, and piping are sewn and top-stitched. The parts are then assembled by stitching on the inside the leather.

The saddle-maker pairs the two flaps with their sweat-flaps, the gullet and front and rear piping. Each pair is machine-stitched 5-times before its assembly is complete.

All mono flap saddle parts are assembled on the same mount and surface. The saddle-maker positions the blocks and foam to adjust thickness. Next, they add a second layer of leather and stitch it down using a sewing machine.

The edges are smoothed and dyed for a clean finish. The Antarès logo is then branded onto the flaps. The flaps are assembled in pairs with the trapeze and pipes.

The saddle panels are made in pairs and sit directly on the horse’s back. They must fit the horse perfectly, which requires special attention.

Harnessing our desire to innovate, we have developed our very own panel design.

DTA (Design and Technology by Antarès) panels ensure the saddle is perfectly adapted to the horse’s back. Their shape provides the maximum surface area for greater contact and shock absorption across the horse’s back.

Each panel is mounted in a piece of wool felt split into three parts: The back line, udder and nose.

Their shape and size matches the horse’s measurements taken at the fitting session.

A “tree shoe” is sewn in to the wool felt to position the tree for assembly. Padding is added to the wool felt panel and then covered in memory foam. Excess foam is trimmed and the edges are sanded to match the panel.

Sanding is a technical procedure that tailors the saddle to the exact shape of the horse’s back.

Each pair of panels is checked and inspected. They must be perfectly symmetrical, rounded and match the horse’s measurements. The technique used to cover the panel in leather varies according to the type of panel (DTA or classic).

This first technique uses moistened leather. The piece of leather is immersed in hot water to make it easier to work with and then gradually attached to the panel structure. Any excess leather is trimmed to leave just the right amount. The leather part is then laced to the panel starting from the back line. The udder and nose parts are the most difficult to lace. The leather must be sufficiently stretched and flattened to remove any wrinkles and creases so that the exposed part of panel is perfectly smooth.

The second technique is specific to DTA panels which have a different shape. Their larger contact area requires additional stitching.

The saddle-maker works with two pieces of leather rather than one. First, they attach both pieces to the panel to trace the curves. The leather is then cut to the exact shape. Both pieces are stitched together along the outlines drawned beforehand.

The subsequent “sock” is then placed on the panel, trimmed and attached using the above technique. This procedure using additional stitching helps remove any wrinkles in the leather.

Building the saddle seat is a very precise process. Several saddle-makers work on the seat, in turns, before it is assembled with the other saddle parts.

The tree forms the skeleton of the saddle and is made of beech wood. Antarès makes its own saddle trees but also uses French suppliers. There are more than 5,000 saddle tree designs, varying in length, width, arch size, shape and type of stirrup bars, etc.

The master saddle-tree maker selects the tree depending on the measurements of both horse and rider. The saddle tree-maker then straps nylon to several points of the wooden structure to create the seat’s surface. Padding and memory foam are then attached and sanded to form a smooth and comfortable surface.

Initial seat stretching involves positioning a piece of leather on the saddle tree. The leather must by perfectly stretched along its length and width, which is core the seat’s comfort. Too much tension and the foam will be flattened, too little and the leather will slide and wrinkle. Leather is a unique material and its suppleness varies from hide to hide. The initial stretching process is highly technical, it involves hard-earned expertise gained over the years.

The seat is attached to the skirts with hand-sewn seams. Our seamers check the saddle tree and leather to verify saddle symmetry. They mark reference points (using different sized templates) to then sew the seams. The leather is then removed from the tree and cut to the shape marked out. The reference points for the seams are symmetrically added to the skirts. The saddle design may require clamps on the cantle. A clamp snap ring is then machine sewn to the cantle.

The seat is assembled by hand to the skirts. A finished seat requires 200-300 stitches and several hours’ work.

Once the parts have been assembled, the leather is permanently attached to the saddle tree. The seams are softened with hammer to prevent any discomfort when seated. The front of the seat is attached to the saddle tree using the reference points and then nailed down. The leather is stretched to the edges, while the seams slide under the wooden tree. Once the seat is positioned correctly on the tree, the leather is stapled to the tree and carefully trimmed back. The seat is then ready to be assembled with the other parts.

The previously completed parts are now gathered for final assembly. They are assembled by saddle number: seat, flap pairs and panel pairs.

The flaps are attached to the seat and fastened to the saddle tree with an additional piece of leather, trimmed to size.

The rear piping and the gullet are added to the saddle to entirely cover the saddle tree and hide the saddle frame. Saddle pins are screwed to the front of the skirts. The panels are the final parts to be added. They are attached to the other parts using three different fastenings.

The panels are initially mounted on the tree by attaching them to the inner side of the “tree shoe”, slipping them over the tree billets.

The panel edges are then attached at several specific points with “flies”, small cotton-coated screws. Finally, they are laced along their entire length with a curved needle and thick thread.

Once assembled, the saddle is oiled to nourish and protect the leather.

After drying for several hours, and once all the oil has been absorbed, the saddle undergoes a final inspection. The quality of leathers, their reaction to oiling, the work of our master saddle-makers….

Leather dilates when oiled, so otherwise invisible marks and scars do frequently appear.

There is all scrutinised by more than 65 inspection points for each and every saddle. If any flaw in the leather or production process is detected, the saddle is disassembled to replace the defective part.

Much more than a tailor-made leather saddle, it is a complete experience that we offer you. Our services are the guarantee of a personalized and regular follow-up. Our team of experts is at your side to advise and support you.